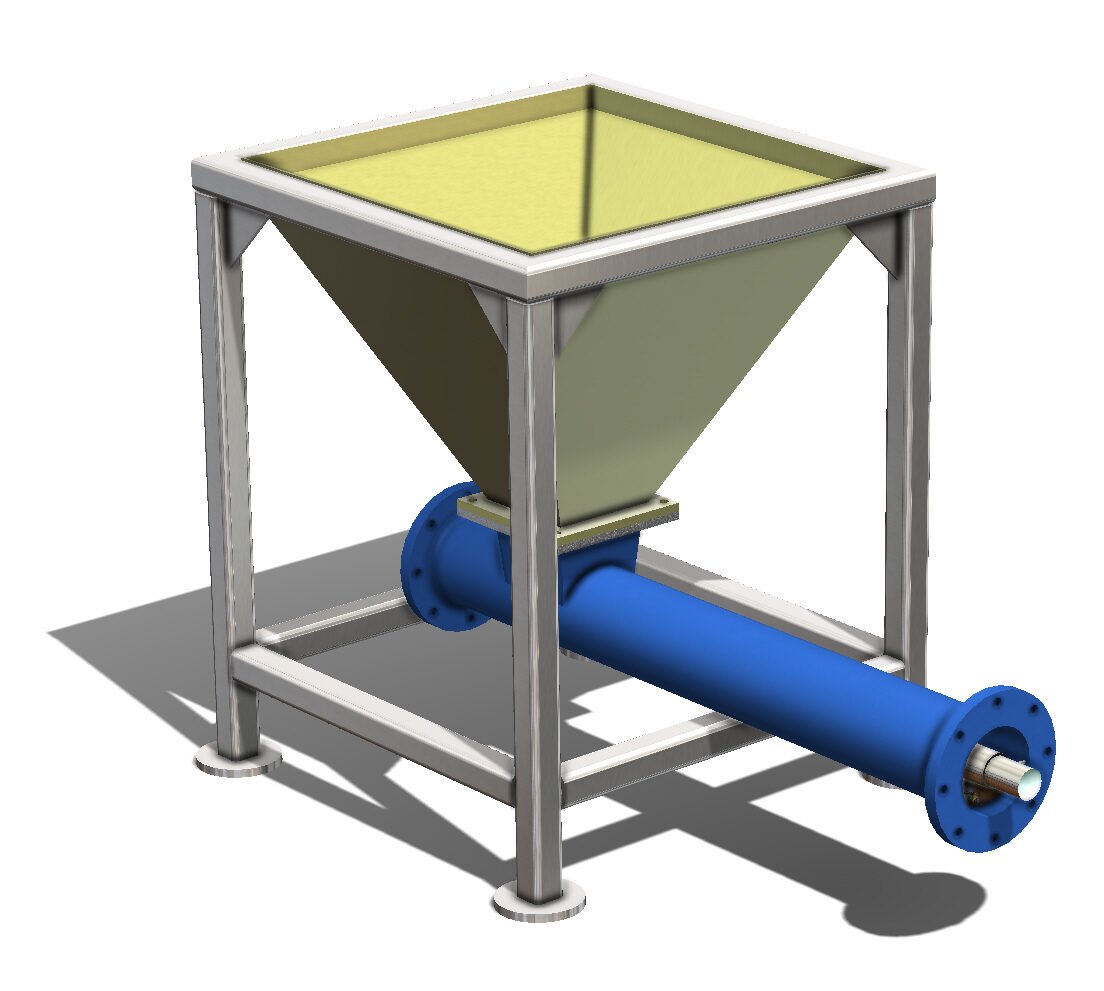

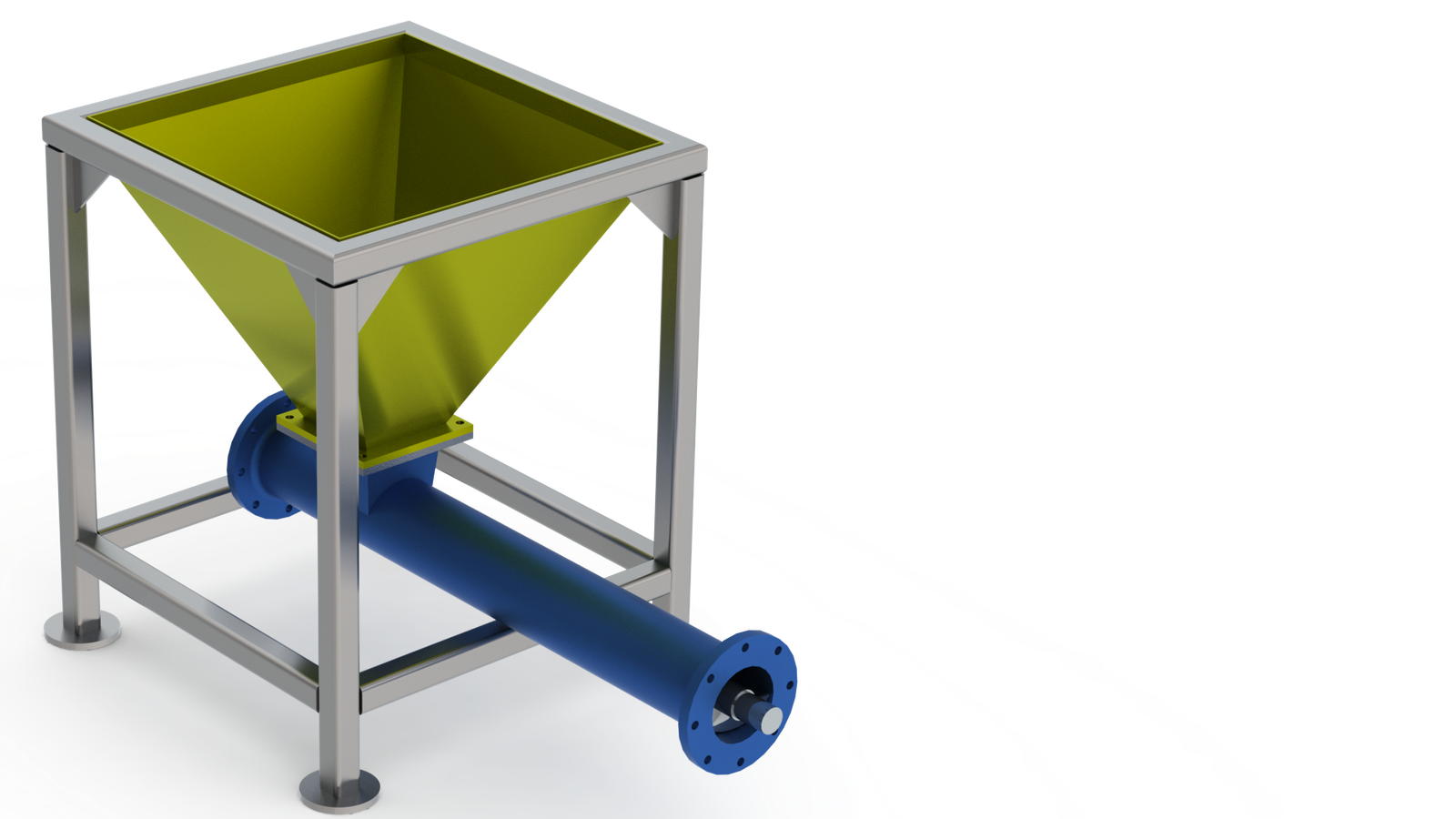

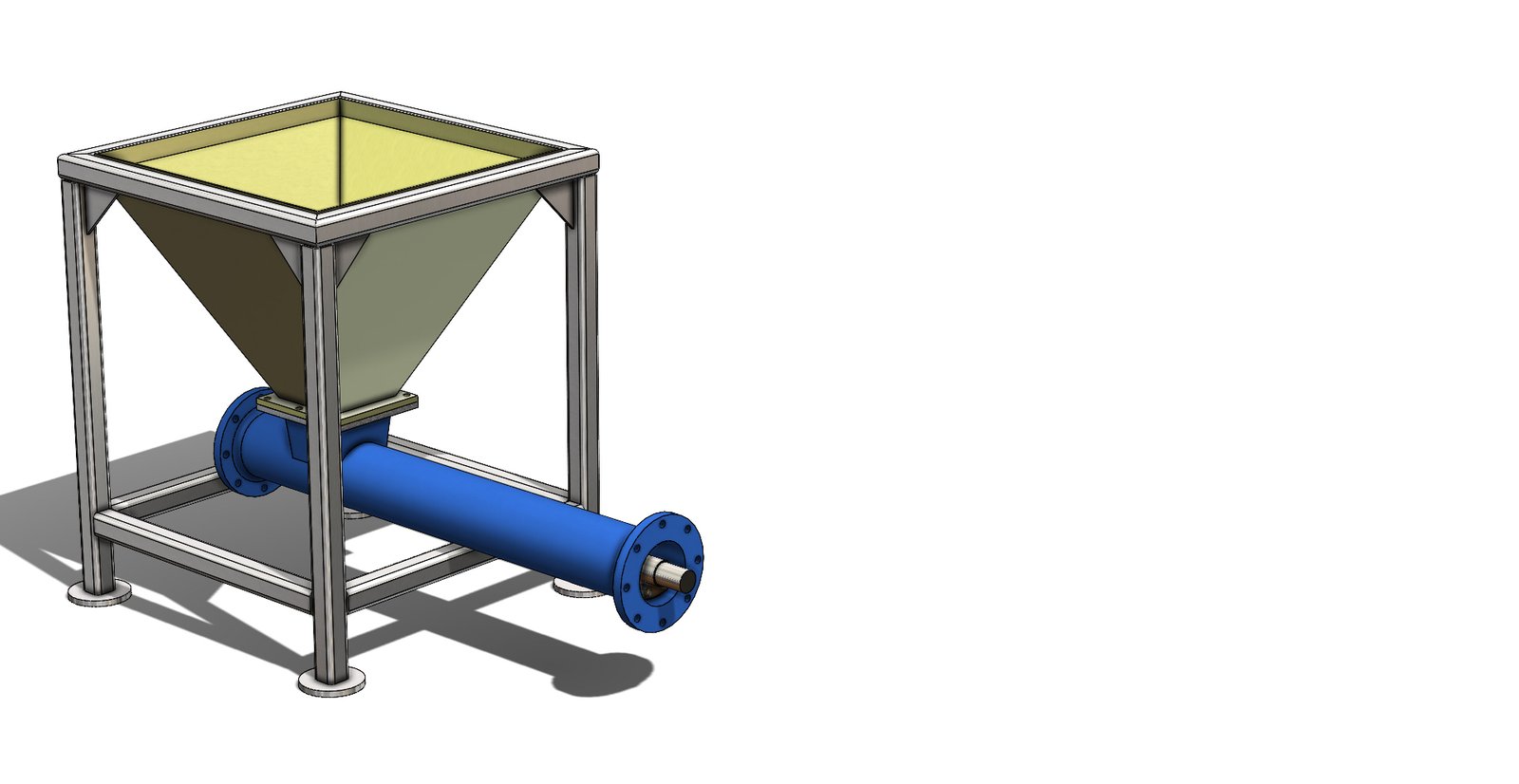

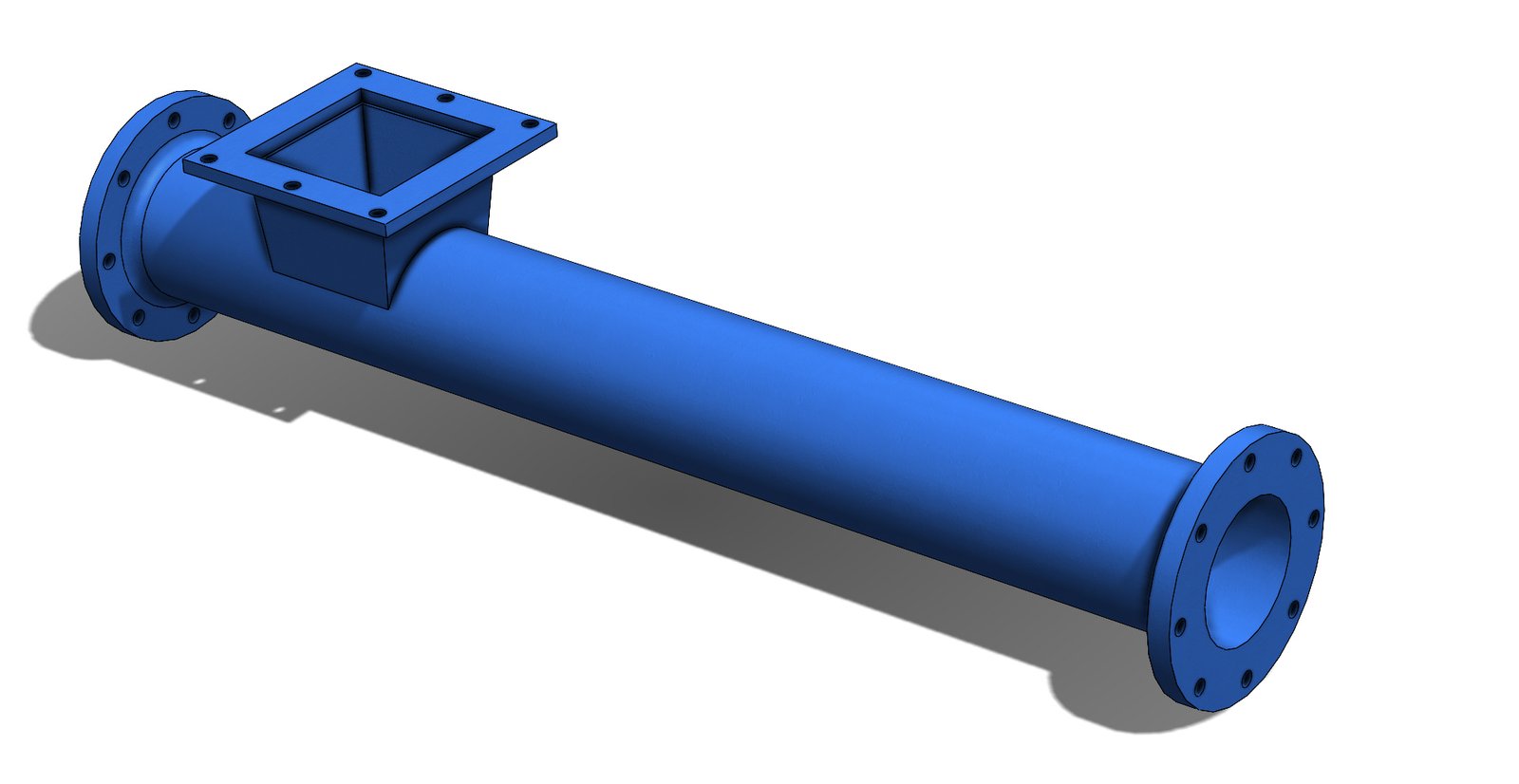

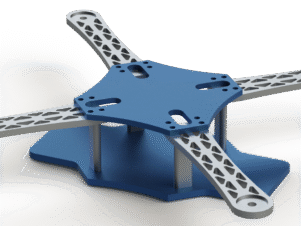

DesignWithAjay | Feeding Hopper Conveyor #374

Original price was: ₹2,000.00.₹990.00Current price is: ₹990.00.

Feeding Hopper Conveyor #374—Engineered for efficient material intake and smooth transfer, ensuring optimal workflow in industrial processing systems.

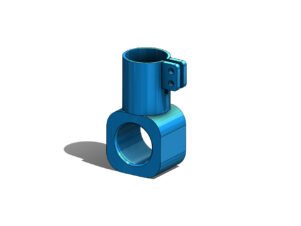

• File Formats: Available in STEP, DXF, and IGS for seamless CAD integration

• Use Case: Ideal for controlled material feeding in automated production lines

• Delivery: Instant digital download for quick access

• License: Personal/non-commercial use (no redistribution allowed)

Description

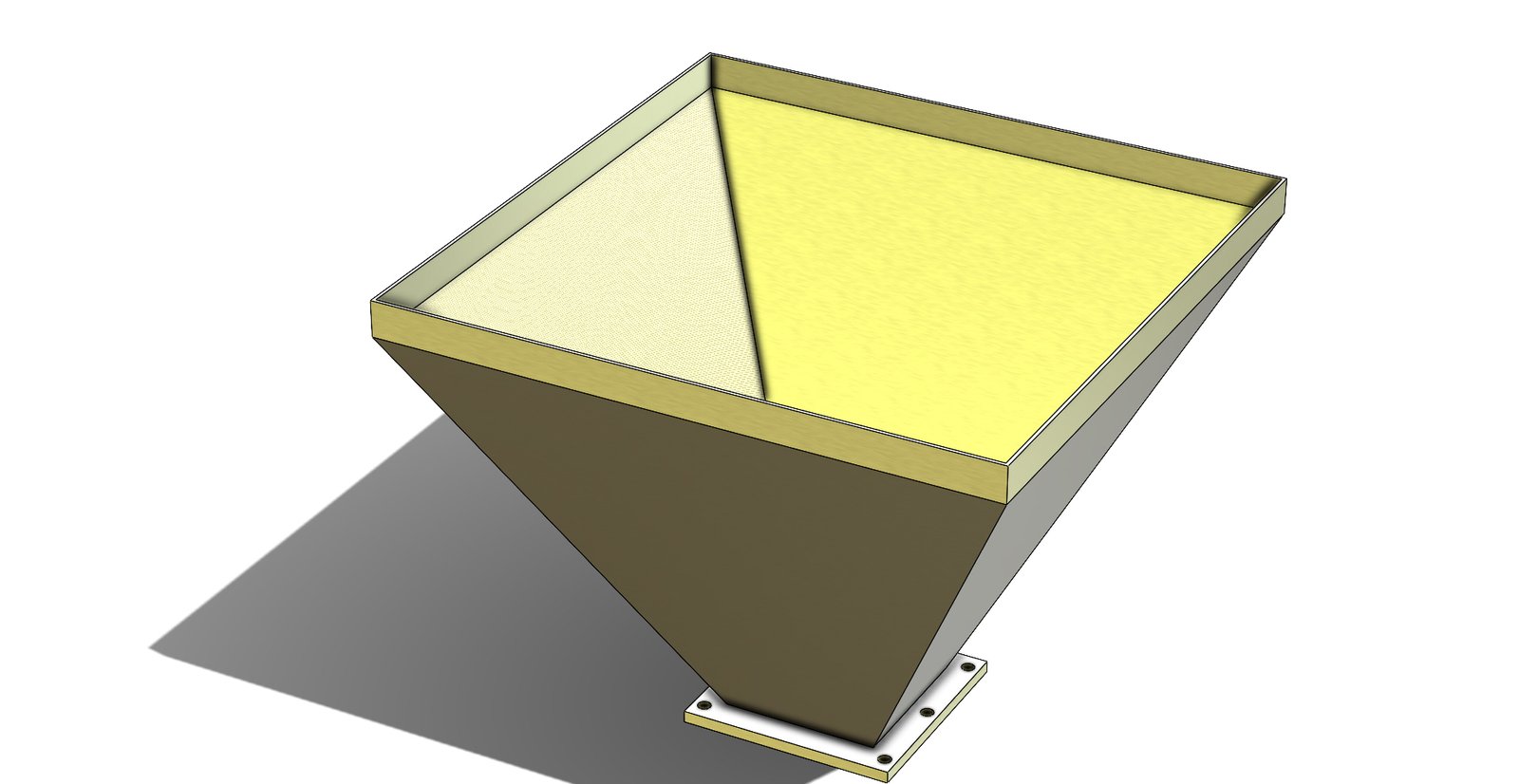

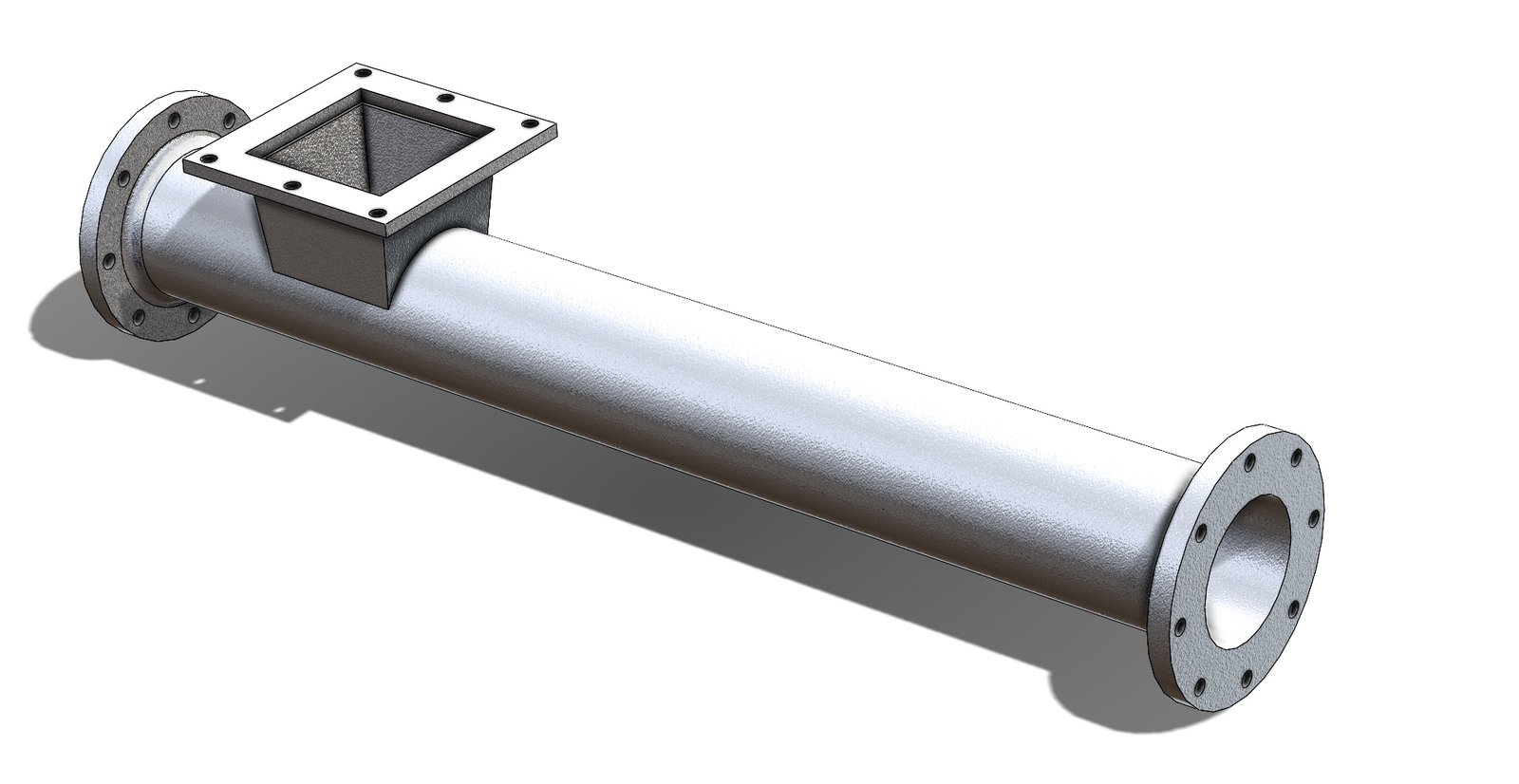

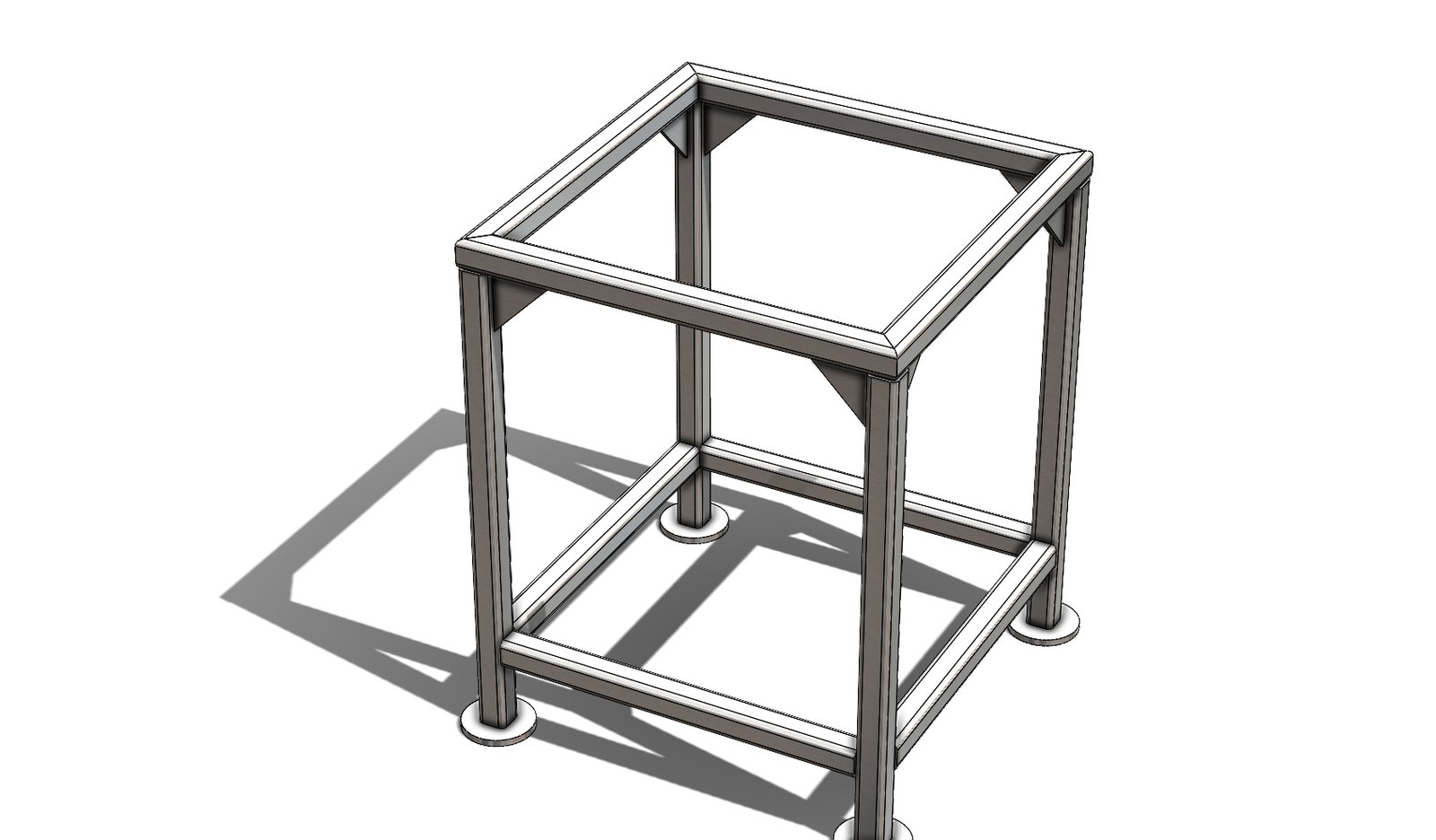

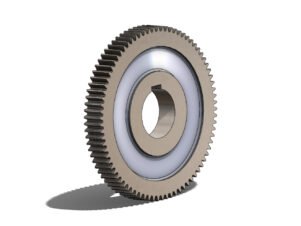

Feeding Hopper Conveyor #374—Exclusively available at DesignWithAjay, this precision-engineered conveyor system is designed for efficient material feeding and handling, combining reliability, durability, and ease of use. Equipped with a hopper for controlled material intake, this conveyor is perfect for applications in manufacturing, processing plants, and bulk material handling industries. Delivered in STEP, DXF, and IGS formats, it integrates seamlessly into design simulations and engineering workflows.

At DesignWithAjay, we specialize in creating Special Purpose Machines (SPM) and high-performance industrial solutions that enhance operational efficiency. The Feeding Hopper Conveyor #374 is meticulously crafted for smooth operation, consistent material flow, and robust durability. This conveyor is ideal for handling a wide range of materials, from granules to bulk solids, with minimal spillage and optimized throughput.

This expertly designed 3D model is ideal for engineers, manufacturers, and industrial designers focused on applications such as assembly lines, material processing systems, and bulk material distribution. Its detailed design ensures smooth integration into various workflows, with a focus on maximizing productivity and minimizing downtime.