About Us

Ajay Industries is a design-led industrial machinery manufacturer based in Bangalore, founded by engineers who spent years designing plastic shredders on screen before ever cutting the first plate on the shop floor. The company grew out of a simple belief: a shredder should be treated like a critical machine tool, not a disposable piece of scrap equipment.

Every machine starts as a detailed 3D model, with stress points, clearances, and maintenance access designed long before fabrication begins. The same person who designs the rotor in CAD also stands next to it during final assembly, ensuring that what was imagined on the screen actually works on the factory floor.

Ajay Industries focuses on plastic shredders and special‑purpose machinery for recyclers, manufacturing units, and R&D labs that need more than a catalogue model. Many customers come with unconventional problems—odd scrap geometry, space constraints, high contamination, or limited power—and the team treats each project as an engineering puzzle rather than just “another order.”

Instead of chasing volume production, Ajay Industries deliberately keeps the batch size low and the engineering depth high. The workshop is set up like an extension of the design office: drawings are live documents, improvements from each build cycle are fed back into the next design, and a machine leaving the factory today is never identical to one supplied years ago.

Why choose US?

- Specialized in plastic shredding and recycling equipment

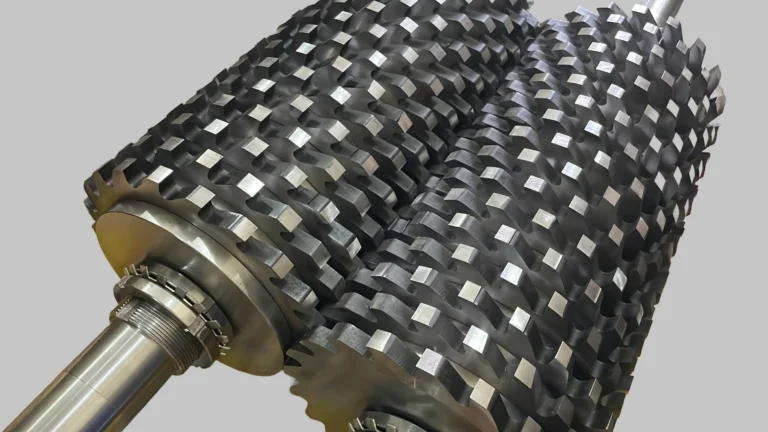

Ajay Industries focuses on plastic shredders and related recycling machinery instead of trying to build every type of machine, which allows tighter optimization of rotor design, blade profile, and drive systems for high efficiency and consistent particle size.

- Engineering-driven, not just fabrication

Every project starts with load calculations, material selection, and safety considerations, supported by detailed CAD models and engineering drawings rather than trial-and-error builds. This approach reduces downtime, improves service life, and makes future upgrades or part replacements straightforward for plant teams.

- Custom-built for your material and process

Instead of pushing a standard catalogue model, Ajay Industries tunes hopper geometry, shaft configuration, blade material, screen size, and drive power around your specific input material and required output. This results in lower energy waste, fewer jams, and better alignment with your downstream processes like washing, extrusion, or baling.

- Built for Indian industrial conditions

Machines are designed to cope with voltage fluctuations, mixed scrap quality, and demanding shop-floor environments common in Indian manufacturing and recycling plants. Components are selected for ease of local sourcing so that customers are not locked into expensive imported spares or long lead times.

- Design-first manufacturing Most manufacturers start from the plate; Ajay Industries starts from the load path. The team designs around where forces actually travel in your machine, which is why bearing housings, gearbox selection, and rotor geometry are treated as one integrated system instead of separate purchases. This reduces failures that usually appear after a few months of heavy use.

- Machines tuned to your scrap, not the other way around Instead of asking you to “adjust your process” to match a standard model, the shredder is tuned to your real scrap profile—density, shape, contamination, and fluctuations in feed. Hopper angle, knife layout, shaft speed, and even maintenance access are adjusted so operators can work with the machine comfortably, shift after shift, without constant jams and stoppages.

- Transparent engineering, no black box You get more than a nameplate with motor power and capacity. Ajay Industries shares how the configuration was chosen—torque margins, knife overlap, safety factors—so your technical team knows exactly what the machine is designed to handle. This transparency builds trust and makes it easier for you to justify the investment to management or project owners. Built for the “second year”, not just the first week

How it Works ?

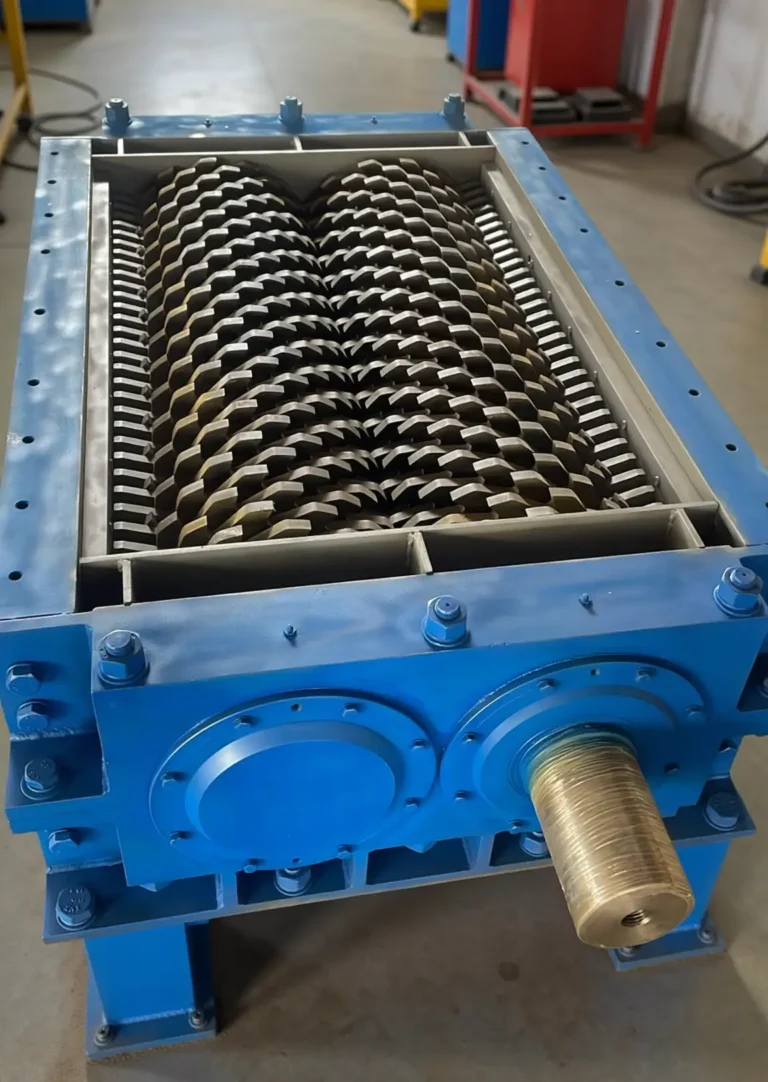

Our shredders combine rugged mechanical design with smart engineering: material feeds into the cutting chamber where twin shafts equipped with heavy-duty blades reduce it into uniform, manageable pieces. The output size is controlled via customizable screens, ensuring your process flows smoothly and efficiently.

Applications & Industries We serve a broad spectrum of industries including:

This is the typical workflow from enquiry to commissioning for a new plastic shredder or custom machine. You can present this as a numbered process section on your page.

- Step 1: Understanding your reality The process starts with a conversation about your plant, not about models and prices. You share what you are shredding today, what you plan to shred tomorrow, how your operators work, and what your ideal output looks like. Photos, videos, and rough sketches are all welcome; the more context, the better the design.

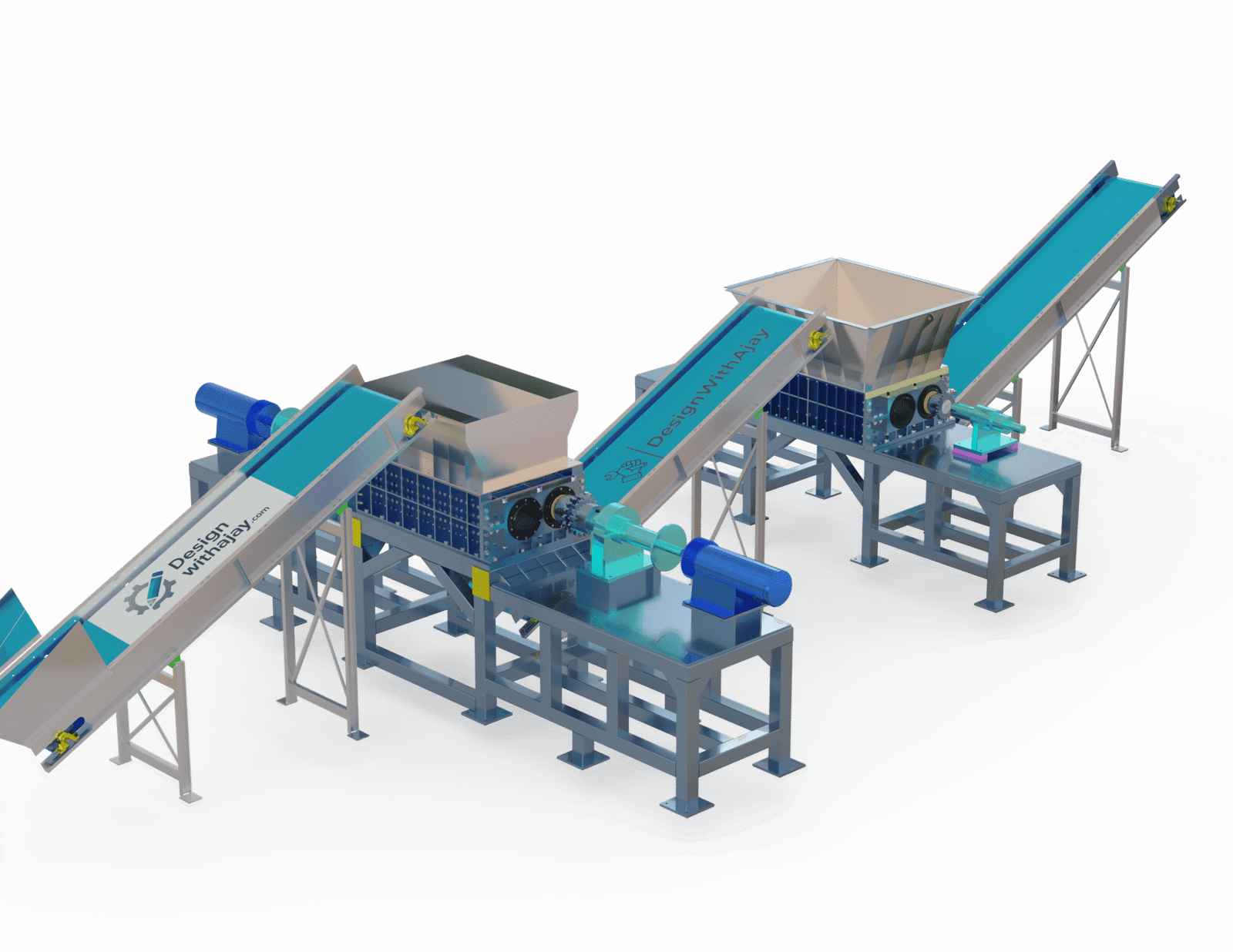

- Step 2: Designing around constraints Ajay Industries then designs a solution around your constraints—available floor space, power supply, handling equipment, upstream and downstream machinery, and required throughput. Instead of forcing a standard footprint into your factory, the layout is shaped so that your material and people can move logically and safely.

- Step 3: Showing you the machine before it exists Before fabrication, you see 3D views or layout drawings that make the machine and its surroundings easy to understand. At this stage, you can ask for adjustments to clearances, service doors, or discharge height. It is much cheaper to move pixels than to move steel, so this is where most fine-tuning happens.

- Step 4: Building with future maintenance in mind During fabrication and assembly, every decision is checked against one question: “Can this be serviced quickly on a busy day?” Knife replacement, bearing lubrication, screen access, and cleaning points are arranged so that your maintenance team does not have to fight the machine to keep it running. This mindset often matters more than one extra kilowatt of power.

- Step 5: Proving performance, then handing over Once the machine is ready, it is test‑run and fine‑tuned so that torque, vibration, and output size are within the design window. When it arrives at your site, commissioning is not just about starting the motor; it includes training your operators on what the machine “likes” and “dislikes,” how to listen for early warning signs, and how to adapt settings to different types of scrap.

- Step 6: Continuous improvement, not a one‑time sale After handover, feedback from your plant is deliberately captured and fed back into future designs. If your production mix changes or you decide to expand capacity, the original design files make it easier to add stages, change screens, or tweak drives without starting from zero. Over time, your shredder line can grow with your business instead of being left behind by it.

Customer Success Stories

Our mission is to enable businesses to enhance their recycling processes with innovative machinery engineered for optimal performance and minimal downtime. We are committed to quality craftsmanship, cutting-edge technology, and exceptional customer support, ensuring our machines add real value to your operations.

Our Projects

Explore our dynamic project gallery where cutting-edge industrial solutions come to life through captivating images, illustrating Ajay Industries’ commitment to innovation and transformative impact in recycling and shredding technology.

CONTACT US

Let’s Power Your Plastic Shredding Projects – Contact Us Today!

Connect with our Bangalore-based experts for specialized support with your plastic shredding machine needs. Whether by email, WhatsApp, or an in-person visit, we’re ready to help you choose, customize, and optimize the perfect shredding solution for your operations.

Office Address

Yelachenahalli, Naidu Layout, Bengaluru, Karnataka 560078

Visit us in Bangalore to discuss your CAD needs in person.

Customer Support

WhatsApp: +91 9448542846

Email: support@designwithajay.com

We’re dedicated to helping you with fast, reliable support.

Business Hours

Monday – Friday: 8 AM – 8 PM

Saturday: 9 AM – 5 PM

We’re here to support your projects during these hours!